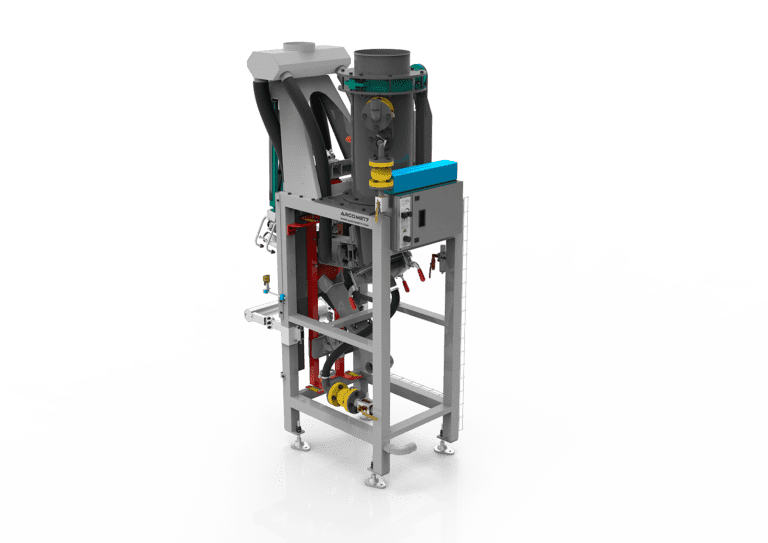

Big bag filling system

Big Bags filling systems allow the bagging of products in large bags in a convenient and easy way.

Different Big Bag fillers depending on the product’s characteristics.

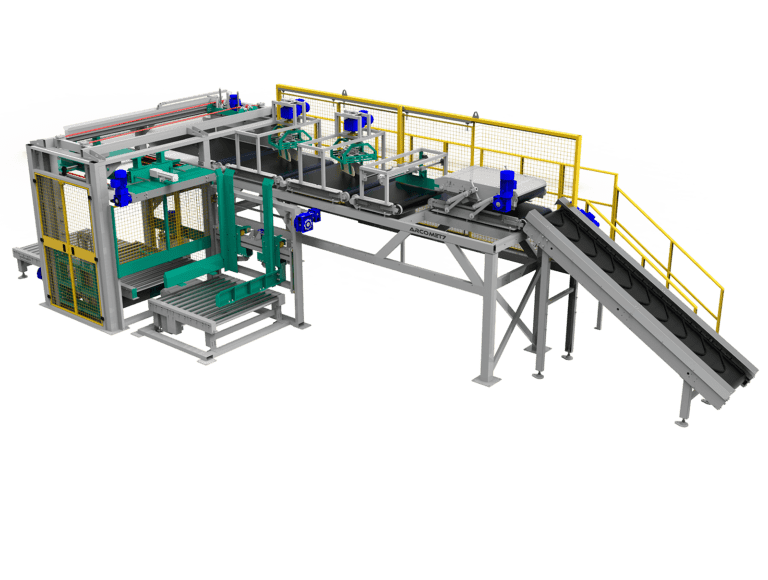

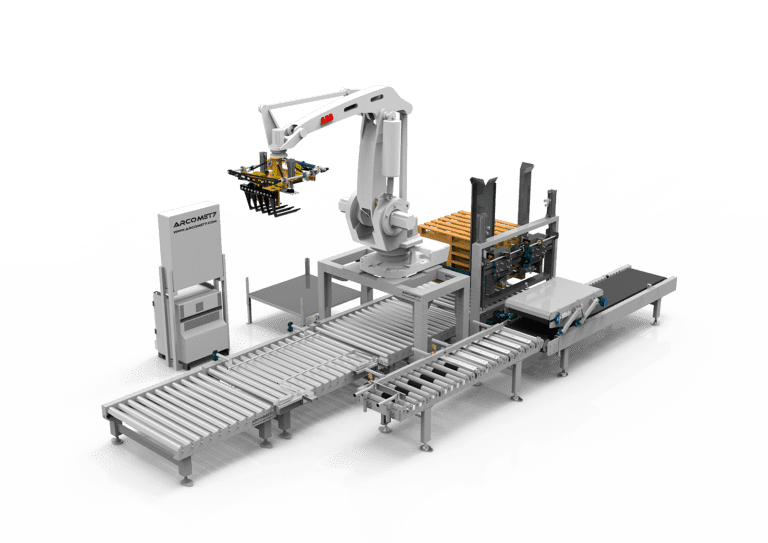

The system of extraction of the big bags can be done by means of a forklift or automatic with a track of rollers

Field of application for all product types to be presented in this format:

- For regular flow products, such as:fertilizers, cereals, seeds, pellets, etc.

- For irregular flow products, such as: flakes, feed, etc.

- For powdered or low granulometry products: flours, salt, minerals, etc.

Benefits of the Big Bag filling system

- Suitable for regular and irregular flow, powder and low particle size products.

- Compatible with 600 to 1800 L sacks and with 4 handles (open mouth, loading or loading/unloading).

- Variety of models: roller conveyor, weighing hopper, weighing platform, support frame and belt feeder.

- Flexible extraction: manual (trolley) or automatic (roller conveyor).

- Compact installation that guarantees minimal maintenance.

- Different types of dosage depending on the product.

Types of Big Bag

Big Bag filling models

- Optimal system for easy filling, weighing and big-bag packing.

- Reduction of the time of big-bag filling, besides a perfect precision with the quantity of product that you want to introduce.

- For certain models, it has touch electronic equipment (AE-9220P.BB) for filling and automating the process.

- Bag volume from 600 to 1800 L

- Support for big-bag.

- Dosing system for filling.

- Blow for sacs system.

- Handle release system.

- Handle positioning system.