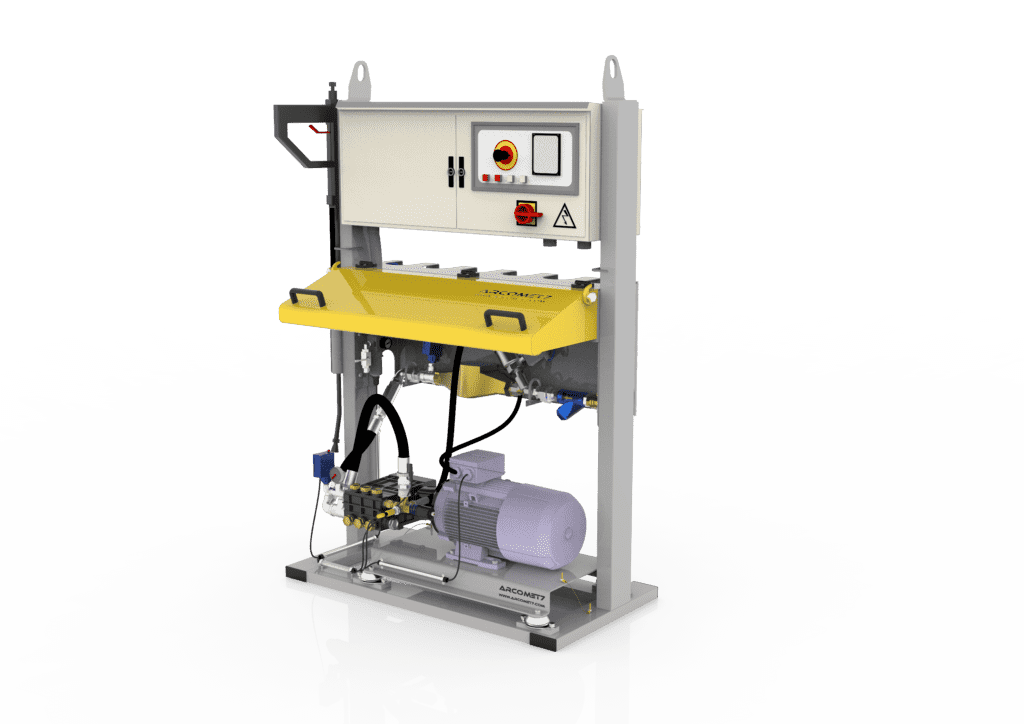

High pressure washing system for mixers that reduces maintenance and extends the useful life of the machinery. It guarantees the safety of workers and also reduces downtime.

The mixer cleaning cycle is carried out by the washing system and is produced by high-pressure water jets and can be done in two ways:

- Automatic: through pressurized water jets thanks to the use of rotating heads placed in the mixer.

- Manual: by using a lance through which pressurized water comes out, with which the operator cleans the interior of the cubicle.

There are different models depending on the number of heads that are placed in the mixer. The electrical cabinet is common for all the models, but changing the contactors and the thermal ones.

Electro-welded steel cabinet, consisting of:

– Lower module for mechanical elements.

– Insulated upper module for electrical elements.

– Removable panels.

It protects all the elements of the system against the outside environment and the weather, and is capable of damping the sound level.

The purpose of the washing system is to supply high pressure water to the washing heads models RH-400 / RH-550. These heads, through their mechanism and their 2 fan-shaped nozzles, are capable of distributing the water at 270º.

The AE-9220V2 control system makes it possible to optimize cleaning, since it synchronizes the installed heads, allows customizing the operating times of each head, and parameterizes the amount of water that the operator wishes to use. Thanks to this control system, it is possible to take advantage of the water used in cleaning, discounting it from the total amount of water for dosing the next cycle.

NEW - WASHING SYSTEM WITH ENCLOSURE

System fairing to dampen the noise level and protect all the mechanical elements that compose it.