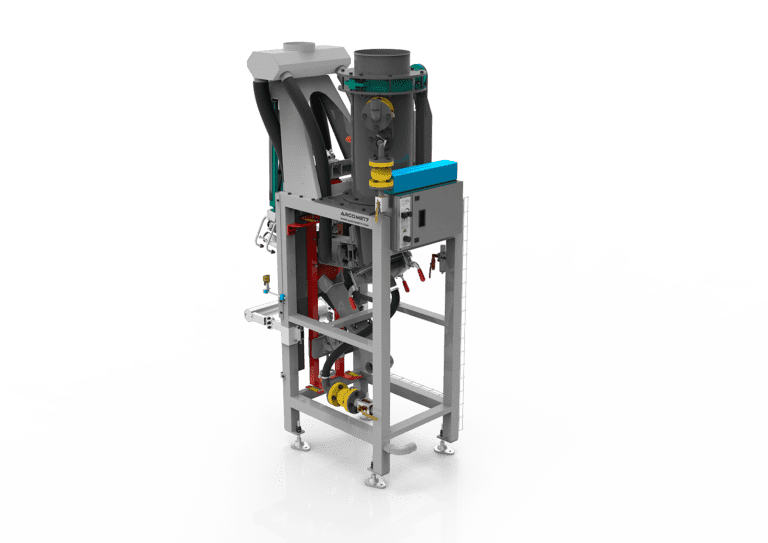

Robot Palletizer

Industrial robot for palletizing and transporting pallets, boxes and sacks depending on the gripper:

Robotic palletizing cells are automated systems designed for low and medium production. They allow palletizing from one or two source lines and shipment to one or two destinations, offering great versatility in formats and configurations.

Thanks to the Arco Central Packaging Software, different types of mosaics can be easily created. The robot’s gripper adapts to the type of item being handled: paper or plastic bags (up to 40 kg), boxes, cans, or bottles (up to 25 kg).

Complete installation on an adjustable bench, including safety fencing and a built-in restraint system. They are easy to clean and require very little maintenance.

Benefits of the automatic palletizing robot

- Compact and easily integrated into any floor plan.

- High versatility of formats: bags, boxes, cans, bottles, etc.

- Possibility of working with one or two origins and destinations.

- Arco Central Packaging software for custom mosaic design.

- Mounted on an adjustable bench with safety systems included.

- Specialized tongs depending on the product: single or double tray, bottle holder, etc.

- Low maintenance and easy cleaning.

TYPES OF MANIPULATING GRIPS

Manipulation and transport of pallets, boxes and bags until 35 Kg.

- Vacuums with extra absorption.

- It allows to hold two bags simultaneously.

- Collection system for empty pallet.

- Pneumatic drives with valve block at 24 Vcc.

- Pneumatic supply at 6 bar of pressure and minimum flow 700 Nl/min.

-

Industrial palletizing robot for palets, boxes and bags up to 40 Kg.

- It allows to hold two bags simultaneously.

- Allows to pick up a bag (gripper tray)/Allows to take two bags at the same time (gripper tray double).

- System of manipulation and transport boxes.

- Collection system for empty pallet.

- Automatic collection system of cardboard.

- Reduced height to leave the load.

- Pneumatic drives with valve block at 24 Vcc.

- Pneumatic supply at 6 bar of pressure and minimum flow 75 Nl/min.

Manipulation of drums until 25 Kg.

- Different dimensions of drums.

- Double fixing system for drum.

- Collection system for empty pallet.

- Pneumatic drives with valve block at 24 Vcc.

- Pneumatic supply at 6 bar of pressure and minimum flow 75 Nl/min.