Palletizer

Inicio » Palletizer

Application sectors

Sand | Mortars | Lime | Pellets | Pseudo-foodstuffs | Powders

Sand | Mortars | Lime | Pellets | Pseudo-foodstuffs | PowdersAutomatic end-of-line palletizer

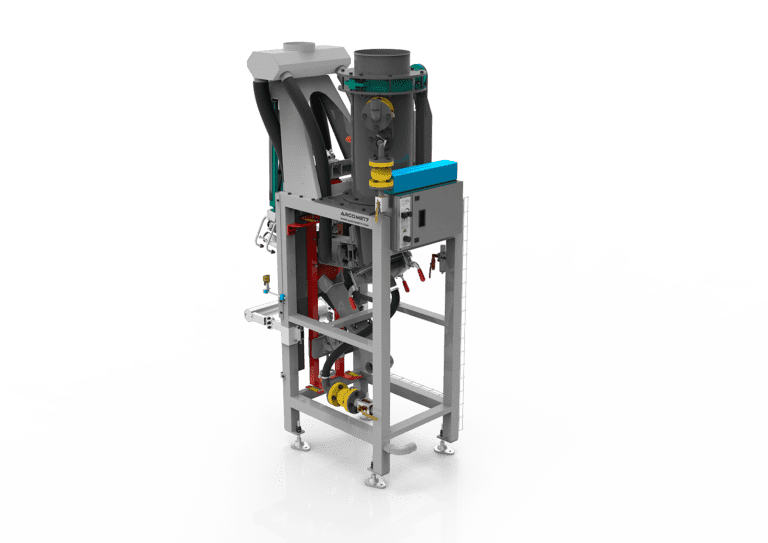

At Arcomet7 we are manufacturers and designers of palletizing lines, where we integrate individual palletisers and complete lines with industrial bagging machines and automatic stretch wrappers..

We have 3 types of palletizers, configurable and customisable for each process in your sector and company. In addition, they are integrated with automation for the control and visualization of all movements and safety of the palletizer:

SAFETY:

- Security fence control (2 lower and 2 upper gates).

- Safety barrier with muting at the elevator exit (1 unit).

- Supply of all detection sensors.

PALLETIZER SOFTWARE:

- Process visualization.

- Graphic curves of consumption, speed and torque.

- Simple and intuitive handling.

- 11 Predefined mosaics.

- Real-time alarm notification.

- Preventive maintenance of all elements.

TYPES OF PALLETIZER

- Bravo Basic palletizer → 1200-1400 bags/h.

- Bravo One palletizer → 1500-1800 bags/h.

- Bravo Two palletizer → 1600-2000 bags/h.

Benefits of the automatic palletizer

- High production with great precision.

- Customizing mosaics.

- Easy operation via touch panel.

- Real-time visualization of the process, alarms and consumption.

- Integrated preventive maintenance system.

- Total security and automation control.

- Perfect integration with complete bagging and wrapping lines.

- High production: from 1200 to 2000 bags/hour (depending on the model).

- Air consumption: between 100 and 200 L/min (depending on model).

- Drive: combined pneumatic/hydraulic system.

- Pallet Dimensions: compatible with formats from 800×1200 mm to 1200×1200 mm.

- Loaded Pallet Height: up to 1400 mm.

- Maximum weight of the pallet: 2000 kg.

- Control software: process visualization, performance curves, and 11 predefined tiles.

- Pneumatic bagging machine

- Continuous bagging machine.

- Wrapping.

- Arco Central Packaging Software.