Double bag vertical bagging machine | ECF-BS

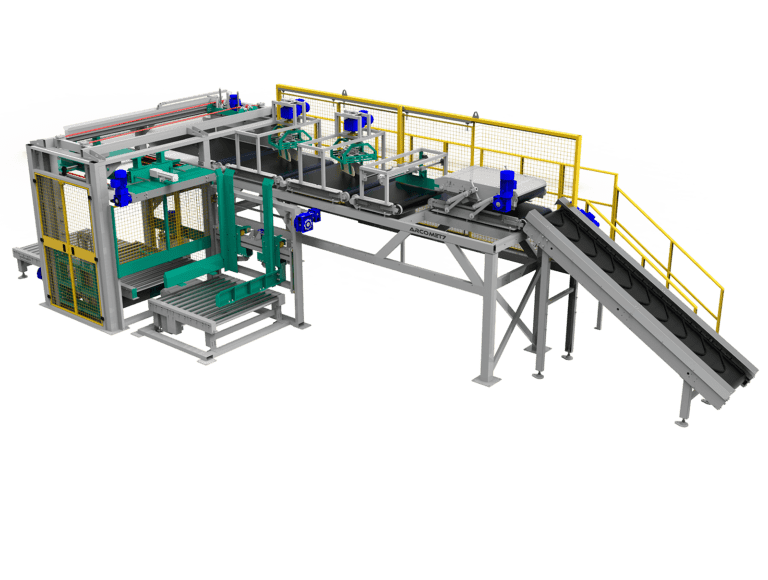

Vertical bagging system FFS for double plastic bags

Bagging system with flat reel that allows a continuous production and automates the three processes of the bagging: it forms, fills and seals the bags.

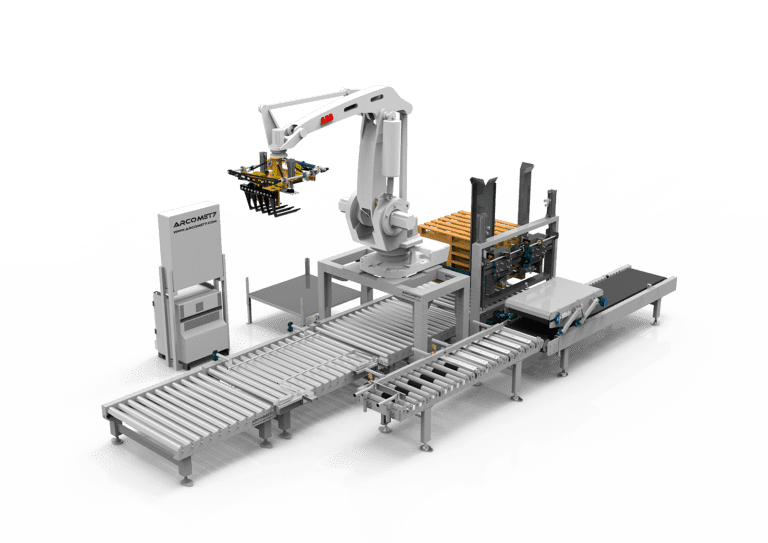

Manufacture of machines for filling polyethylene bags, with two independent departments.

Benefits of the FFS Bisaco vertical bagging machine

- High production.

- Management program designed for simple and intuitive operation.

- Product dosage by volume and by weight.

- Bags with different finishes: die-cut and double die-cut.

Some of the products to be bagged include:

Sands, silica, mortar, gravel, micro concrete

Pearls, detergent, rice

Manures, peat, pellets, fertilizers

Seeds, pet food, granular fertilizer, pellets.

Main elements:

- Frame profile and cold rolled steel sheet.

- Shaper of sacks made of stainless steel.

- Vertical and horizontal sealing of bags.

- Transmission zone and drag film.

- Automatic detector end of film. Automatic forming, filling and sealing of bags pillow type.

- Process control with Arco Diamond packaging software installed on a 12.1″ touch panel PC.

- Visualization of alarms and reminder of maintenance.

- Forms for the products to be dosed (Inventory control) Temperature control and regulation, sealing.

- Multi-language platform.

- Information Manager.

Production depends of size of bags, type of product, and mode of work

- Conveyor belt.

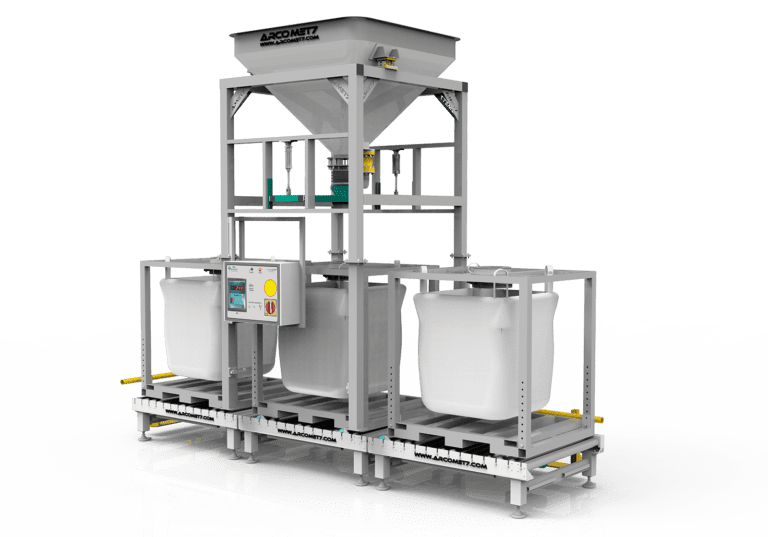

- Dosing system.

- Pre-weighing scale.

- Storage for additional tubes to produce bags of different sizes.