Complements

Sleeve Filter, Screw conveyor transport and micro-dosing for solid additives

Complements

Previous

Next

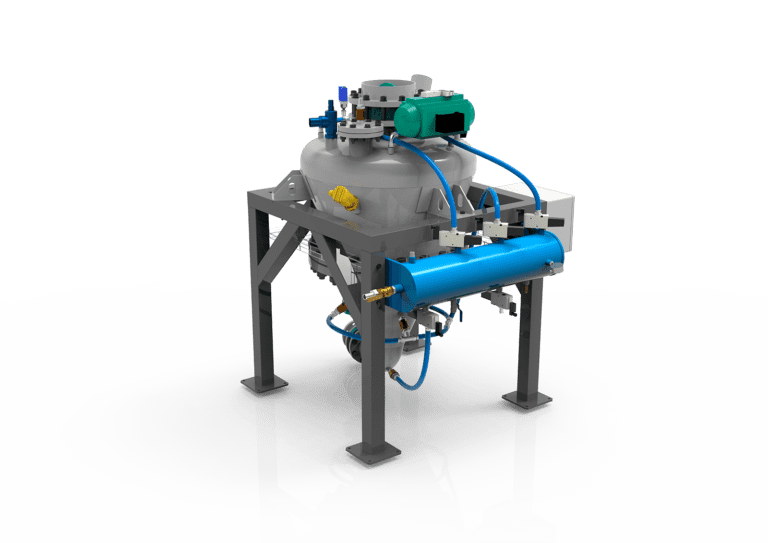

Sleeve Filter

Filters for automatic cleaning, separation and filtration of particles in suspension.

- Electronic equipment for the automation of cleaning cycles of sleeves with electronic pressure manometer.

- As another option, differential pressure control. Intelligent control of electro valves and mesuring differential pressure make it possible to have under control the clog degree of the filter so it can be cleaned when necessary.As a consequence, air pressure consumption in the filter can be reduced.

- Air pressure cleaning system.

- Bagging: this filter is recommended for the suction of bagging.

- Pneumatic conveying: is recommended in silo destination product.

- Filter output hopper.

- Collecting pipe.

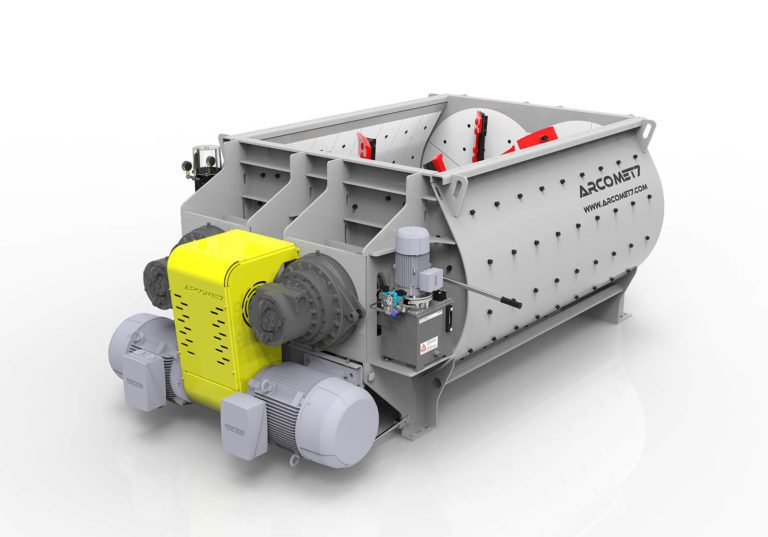

Screw conveyor transport

Dosage system for continuous transport of grain and powdery materials.

It is suitable to different transports: horizontal, vertical (raising) and inclined.

We offer various lengths since we can adapt to your installation and technical features of the product to transport.

- Sturdy design with antirust exterior paint.

- Inspection gate on charge zone.

- Wire fixing system.

- Transport hooks.

- Loading and unloading mouth.

- Engine and gear on the load side.

- Bellows of channeling with clamps.

- Wide range of production: 8, 15, 25, 40 y 60 Tn/h

Previous

Next

Micro-dosing for solid additives

- Micro-dosing for solid additives by screw conveyor.

- Carbon steel construction.

- Inspection system with cover of polycarbonate.

- It includes pneumatic system for quick shut of material.

- Hopper